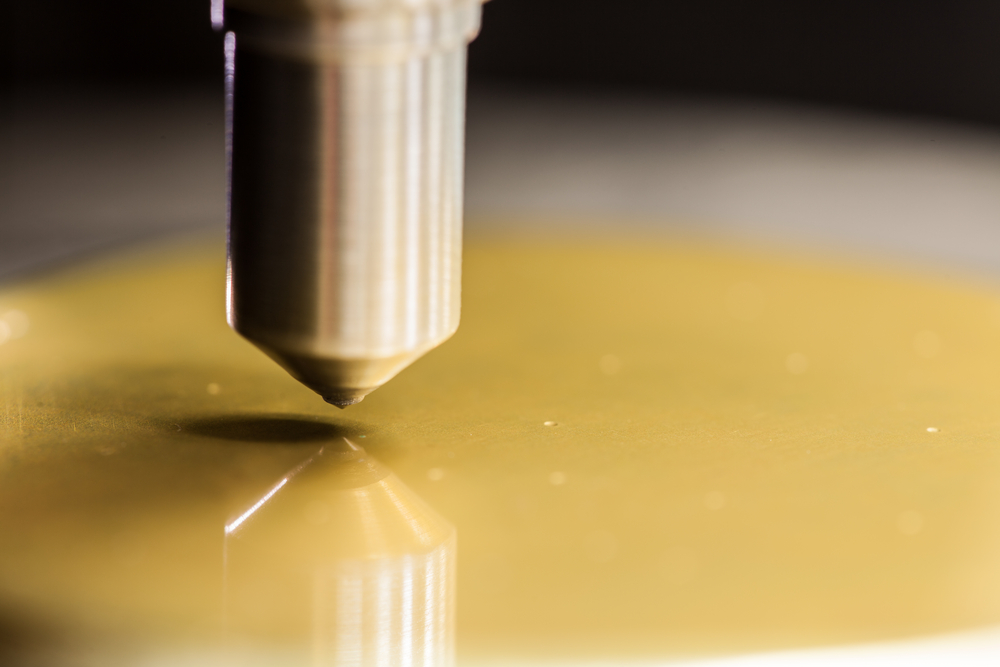

The purpose of hardness testers is to measure the degree of firmness of a material. This firmness, or rather hardness, is an element of the material. The extent of firmness is determined by evaluating the impact on the material’s top when pressure is exerted on it using a sharp or spherical indenter. Its metric of opposition to getting dented is assessed based on the lasting profundity of the dent. In particular, the most effective indenters are commonly made of very solid steel, diamond, or carbide.

Popular Types of Hardness Testers

1. Vickers

This method is fitting for solid and metallic substances, with firmness varying from 10-gram force to 100-kilogram force. The test is performed on exceptionally fine or tiny loads. Subsequently, it is ideal for assessing the stiffness of layers. A single indenter can be used to examine substances with diverse degrees of firmness.

2. Rockwell

Since it makes use of both perforating diamond and steel, this technique is very common when evaluating the hardness of substances. The testing process can be automated and done very swiftly. This is because it is the only hardness testing technique that does not require the use of optical devices.

3. Brinell

For big but less solid metals, this method is the most ideal. The indenter used is made of steel and bears a diameter that relies on the dimensions of the sample under examination. Any kind of metal can be tested using this technique.

Before settling for a particular hardness tester, there are multiple factors that ought to be taken into consideration. Besides the type of material, its depth as well as the dimensions and shape of the sample should be reviewed. This is a proper guide that should give you accurate insights before securing the best hardness testers.

More Stories